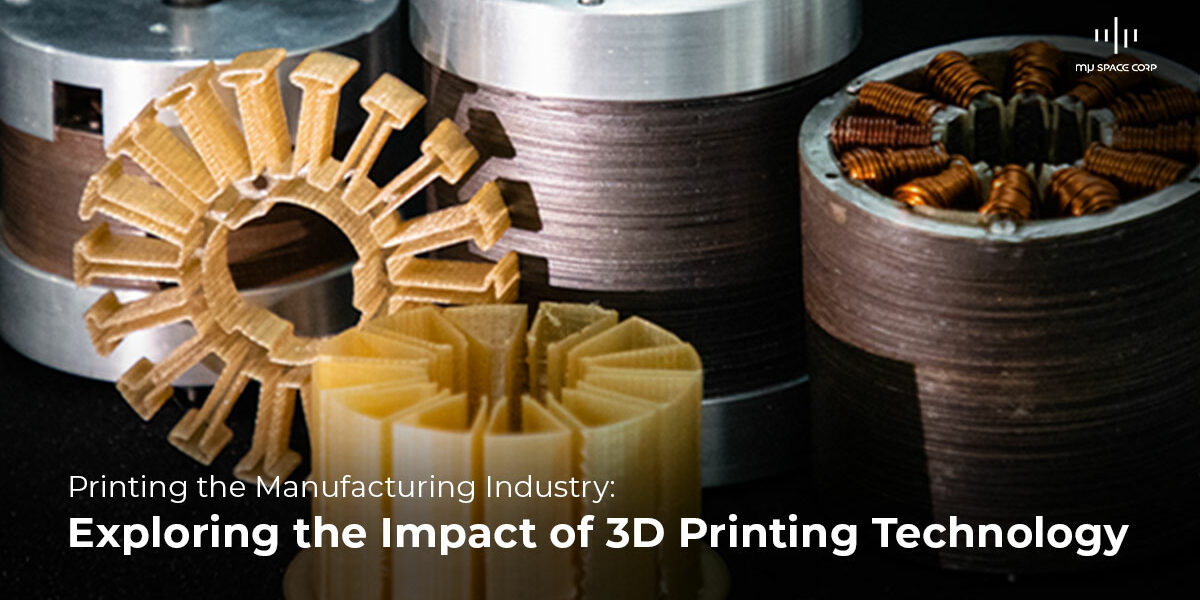

Printing the Manufacturing Industry: Exploring the Impact of 3D Printing Technology

Over the past decade, 3D printing technology has become an increasingly popular tool in a variety of industries, including aerospace. 3D printing has the potential to revolutionize aerospace engineering by allowing for more rapid and cost-effective prototyping, customization of parts, and innovative design approaches. mu Space Corp, a satellite manufacturer, and satellite internet service provider, has a 3D printer at its facility, mu Space Factory 0. Factory 0, is 1 of the 3 running factories, and it is the main hub for additive manufacturing.

How does a 3D Printing Machine Function?

Unlike subtractive manufacturing, which requires materials to be removed or cut apart to create a product, additive manufacturing adds layers to create the product. 3D printing, a form of additive manufacturing, prints layers of materials on top of each other to create the desired product. In the case of mu Space, the product can be either plastic or metal, as the printer used in the facility can print both materials. Before the printing process starts, a design must be created on a computer with the perfect dimensions required, after that it is ready to be sent for printing.

3D Printing in the aerospace industry

One of the most significant challenges in aerospace engineering is the creation of engine components that can withstand extreme temperatures and stresses while remaining lightweight. Traditionally, engine components are created using traditional manufacturing methods, which can be time-consuming and expensive. 3D printing, on the other hand, offers a fast and affordable way to create complex engine parts with unique shapes and properties. A few examples include:

- Prototyping: This allows manufacturers to have a cheap and efficient way to create models before producing the final product.

- Complex Components: Producing custom-made motors and parts using the traditional manufacturing method is expensive and time-consuming. 3D printing eliminates this issue and is able to deliver a high-quality product.

Due to the efficiency of 3D printers and their constant contribution to high-level manufacturing tasks, mu Space took upon the challenge of additive manufacturing. It is used for printing satellite components in order to reduce production time and production costs.

Use-Case of mu Space’s 3D Printer

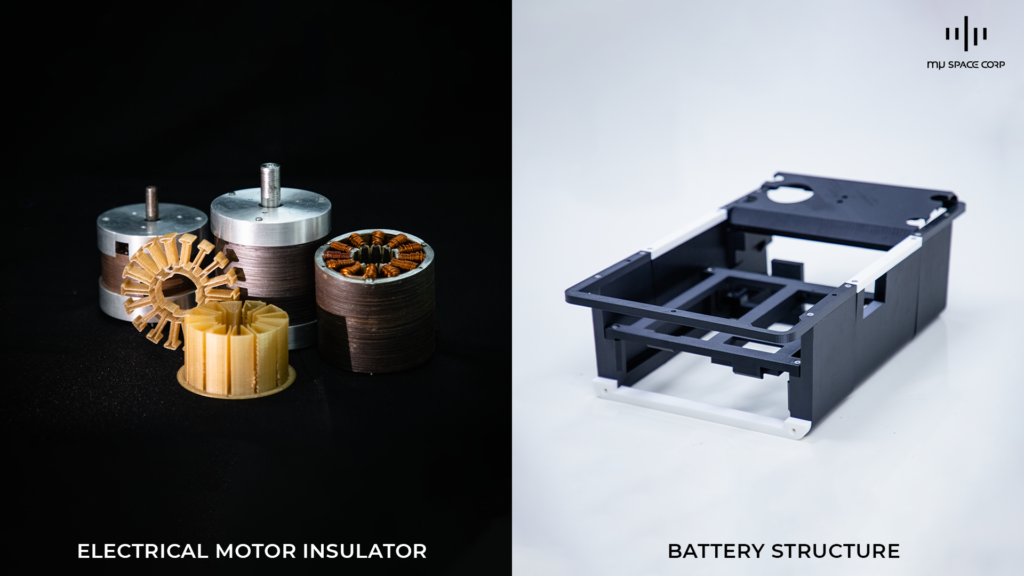

We can produce items with complicated structures using 3D printing, which helps lower manufacturing costs and obtain parts with specific features.

-

-

- For example, we 3D print the internal parts of the motor using materials with high strength and heat resistance, such as PEEK, suitable for engineering purposes. We also print the structure used within the battery, which is one of the items we’re working on for customers. We print this structure to be used for trial assembly prior to further development into real products. Therefore, we choose PLA material, which, although its characteristics are not equivalent to PEEK, is less costly and easier to print, making it appropriate for printing for use in R&D products.

-

Other Use-Cases of a 3D Printer

- Medical industry: 3D printing has been used to create prosthetics, implants, surgical tools, and models of organs or tissues for research and surgical planning.

- Education Industry: 3D printers are increasingly being used in schools and universities to teach design, engineering, and manufacturing skills, as well as to create models and prototypes for various projects.

- Customized manufacturing: 3D printing can be used to create bespoke or unique parts, products, or components on demand, eliminating the need for expensive molds or tooling and reducing waste.

- Architecture and construction: 3D printing can be used to create large-scale models, as well as to fabricate building components or entire structures, potentially reducing waste and speeding up construction times.

In conclusion, the use of 3D printing technology in the aerospace industry has the potential to significantly improve the efficiency, reliability, and customization of aerospace engineering. From the creation of complex engine components to tailor-made parts, 3D printing offers a range of benefits that traditional manufacturing methods cannot match. As the technology continues to evolve, mu Space will continue to innovate applications of 3D printing in the aerospace industry and beyond.

For more information regarding mu Space’s 3D Printing Services, please visit: