Building structures that are sent to space require many moving parts, especially in the manufacturing sector. That is due to high-cost requirements and the abundance of components that go into building the structure. One specific way of manufacturing is known as additive manufacturing, which unlike the more common way of subtractive manufacturing, this way adds layers to create an object and ultimately allows low production volume and low production costs. 3D printers are a major part of additive manufacturing, especially due to their rising prevalence in the manufacturing industry. 3D printers can print both metal and plastic, depending on the machine and the requirements of the organization. mu Space Corp, a satellite manufacturer, and satellite internet service provider, has a 3D printer at its facility, mu Space Factory 0. Factory 0, is 1 of the 3 running factories, and it is the main hub for additive manufacturing.

3D printing technology has been in use since the early 80s and became even bigger when it incorporated metal printing in the late 90s. The Aerospace industry started to utilize this technology in the 1990s however on a much lower scale than it is used today. According to research published in the Journal of Aeronautics and Space Technologies, the aerospace industry makes up for around 15% of additive manufacturing in the market. Due to the efficiency of 3D printers and their constant contribution to high-level manufacturing tasks, mu Space took upon the challenge of additive manufacturing. As mentioned earlier, Factory 0 is the hub of additive manufacturing and features a 3D printer that can print both metal and plastic. The printer is used for tasks such as printing satellite components and using metal as the main material, with the aim to reduce production time and production costs. Therefore, giving our engineering team more time to develop more efficient products and meet the needs of customers.

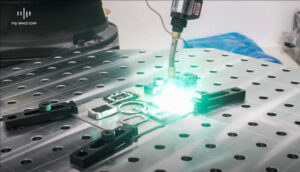

So, how does a 3D printer function? Unlike subtractive manufacturing, which requires materials to be removed or cut apart to create a product, additive manufacturing adds layers to create the product. 3D printing, a form of additive manufacturing, prints layers of materials on top of each other to create the desired product. In the case of mu Space, the product can be either plastic or metal, as the printer used in the facility can print both materials. Before the printing process starts, a design must be created on a computer with the perfect dimensions required, after that it is ready to be sent for printing.

mu Space Corp’s satellite production, the mu-B200, has parts printed at Factory 0 by their 3D printer before being incorporated into the structure itself. mu Space works in a vertical integration strategy, due to the company’s aim to form a supply chain in the region, therefore making additive manufacturing an integral part of their manufacturing process. The company builds everything from components to the final structure in-house, therefore 3D printing allows for a more cost-efficient and time-efficient solution.